You’re a building owner with an upcoming project. Would you like to cut your construction costs while

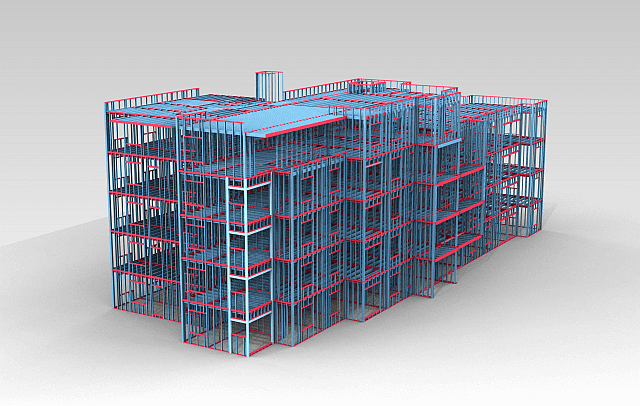

maintaining work quality and output? Of course you would. But how? One answer involves material selection. Cold-formed

steel (CFS) framing has a proven track record of providing cost-effective and sustainable benefits for mid-rise buildings. For example, cold-formed steel framing was chosen for an office renovation at the Chart Industries, Inc., manufacturing plant in La Crosse, Wisconsin, for its cost benefits and flexibility to integrate with other systems. Compared to masonry wall construction, the CFS system saved about $2.50 per square foot on the exterior walls. Additionally, steel is resilient, adaptable, and durable, which reduces life cycle costs. Steel framing systems

can be readily and economically adapted to cope with the changing requirements of occupants, avoiding functional obsolescence and the high cost and disruption of refurbishment, redevelopment, or demolition.

How-to articles on specific construction techniques Exploring the impact of technologies like AI, 3D printing, and drones on construction Sustainable practices, materials, and certifications in construction Articles on best practices for maintaining safety on construction sites Updates on building codes, zoning laws, and other relevant regulations.

Steel building systems offer significant cost benefits over competitive building materials when the total cost of construction is considered. Here are 10 ways that CFS framing systems can lower your total construction costs:.

1: HIGH STRENGTH-TO-WEIGHT RATIO

Steel framing’s strength-to-weight ratio significantly exceeds that of wood or concrete. Being strong and relatively lightweight, CFS

Systems reduce a building’s total load, which, in turn, allows the owner to save costs beginning at the foundation.

2. PANELIZATION

Panelizing CFS wall panels off-site reduces on-site labor costs and construction waste. It cuts the total project cycle time and improves quality control, since CFS components can be created to exact measurements.

3. SHORTER PROJECT CYCLES

The predictability and accuracy of steel components speed up the process and allow follow-on trades to get to work sooner. The shorter construction timeframe reduces interim financing costs for projects. It also narrows the window of construction-related liability and allows for earlier building occupancy, as was the case with a CFS project for student housing at California Polytechnic State University. The project was completed six months earlier than what was predicted for a concrete structural form, saving the university’s budget.

4. BETTER RESULTS DURING WINTER TIME

Ready-mixed supply of CIP concrete during winter construction can add cost to a project And, concrete requires artificial heat in order to cure during cold temperatures. Neither of these costs are associated with steel framing.

5. EARLIER PROJECT COMPLETION AND BUDGET SAVINGS

Steel’s shorter construction cycle means equipment can move on and off the job site faster. This lowers crane costs and reduces scaffold rental times, for example.

6. LOWER INSUANCE RATES

Builders risk insurance premiums are typically lower for steel than for wood. Builders risk insurance for a four-story, 400-unit hotel built over 24 months in Ohio cost $360,000 because cold-formed steel framing was used. It would have cost $1.6 million had it been built with wood—a savings of about $1.3 million.

7. LOWER FIRE-RELATED LEGAL COSTS

Owners of wood-framed, mid-rise buildings need to consider the possibility of legal actions due to a construction or building fire that results in damage to, or destruction of, adjacent properties. This is of particular concern for mid-rise buildings, which are often built on “infill” sites as a method to curb urban sprawl. In 2015, for example, a fire at apartments under construction in Edgewater, NJ, displaced hundreds of tenants from nearby buildings. Lawsuits were filed against the building owner, citing the known risk of fire associated with wood construction. Steel, in contrast, is non-combustible. So, CFS framing minimizes the risk of any fire spreading to adjacent buildings and reduces the possibility for subsequent legal action, putting less burden on building owners and firefighters.

8. NO MANDATED SITE SECURITY

Several Canadian jurisdictions are requiring builders to post 24-hour security guards at their wood-frame construction sites. One builder reported paying up to $10,000 per month for these security details. Another builder said the security needed for a $8 million wood-framed project cost $20,000. Steel-framed projects do not have such hidden or extraordinary site construction costs.

9. NO COSTS ASSOCIATED WITH SITE SAFETY COMPLIANCE

Since wood-framed buildings are highly susceptible to fire during the construction phase, many municipalities in British Columbia, Canada, require developers to submit detailed fire-safety plans when applying for building permits. Some municipalities mandate that sprinklers and standpipes be in place on floors where work is underway. They also require additional safety supervision, such as fire watches during hot work. These costly site safety practices are not required for noncombustible cold-formed steel buildings, providing peace of mind for owners and builders.

10.PRODUCT DURABILITY

Steel is dimensionally stable and does not expand or contract with changes in moisture content. Steel will not warp, split, crack or creep when exposed to the elements. When materials like wood or brick are exposed to moisture, they swell. When dried, wood will warp, crack, chip, split and spall. Concrete and concrete block will shrink and form shrinkage cracks. Dimensional stability concerns are magnified when these types of materials are used in taller mid-rise buildings. Additionally, steel is resistant to termites and rodents.